----------2018.08.02

What are the common printing papers?

In the printing package, we use a variety of paper. When you need packaging advice, Unico Packing will also provide you with the right type of paper depending on the product you want to package. So, what are the common printing papers? And how to choose?

1. White Cardboard

What are the common printing papers?

In the printing package, we use a variety of paper. When you need packaging advice, Unico Packing will also provide you with the right type of paper depending on the product you want to package. So, what are the common printing papers? And how to choose?

1. White Cardboard

Whiate cardboard is a kind of board made of thick and solid pure wood pulp. It's calendered or embossed. It is mainly used for printing and printing substrates. It can be divided to A, B, C according to quality level.

Features, surface and back colors are both white, but the surface is smooth, and the back is rough. Stiffness of white cardboard is good. Good stiffness, suitable for single-layer carton or paper bags, used to pack items that are not very heavy.

Common weight, 210gsm, 250gsm, 300gsm, 350gsm, and 400gsm

General use, single layer carton, paper card, paper bag, and business cards, etc.

2. Duplex Board or Gray-white board

Features: Surface is white color, but back and paper core color are gray. Normally, surface paper of color corrugated boxes use grayboard. And if there is no requirement for the color of the back paper, it is also a good choice to make a single-layer carton to pack small pieces of lightweight items.

The gray-white board paper used for the surface layer of corrugated board is the carton box surface after the box is made. Therefore, the gray-bottom white board is required to have high strength, folding resistance, tensile resistance, wear resistance, puncture resistance and the like. And a certain water resistance, paper is strong and tough, but also must have good appearance and printability.

Common weight: 250 grams, 300 grams, 350 grams, 400 grams, 450 grams

General use: single-layer carton, corrugated box, paper card, tag, etc.

3. Corrugated sheets

3. Corrugated sheets

Corrugated paper is pressed into a corrugated shape during the production process. After corrugated paperboard is produced, it will provide cardboard elasticity, flat compressive strength, and affect the vertical compressive strength and other properties. Corrugated paper, the paper surface is flat, the thickness should be consistent, there should be no paper defects such as wrinkles, cracks and holes, otherwise the broken ends of the production process will be increased, which will affect the product quality.

Corrugated sheet consists of facial tissue, core paper and inner paper, which add cushion to the packaging and protect the products inside.

Number of layers of sheet: 3 layers of corrugated sheet, 5 layers of corrugated sheet, etc.

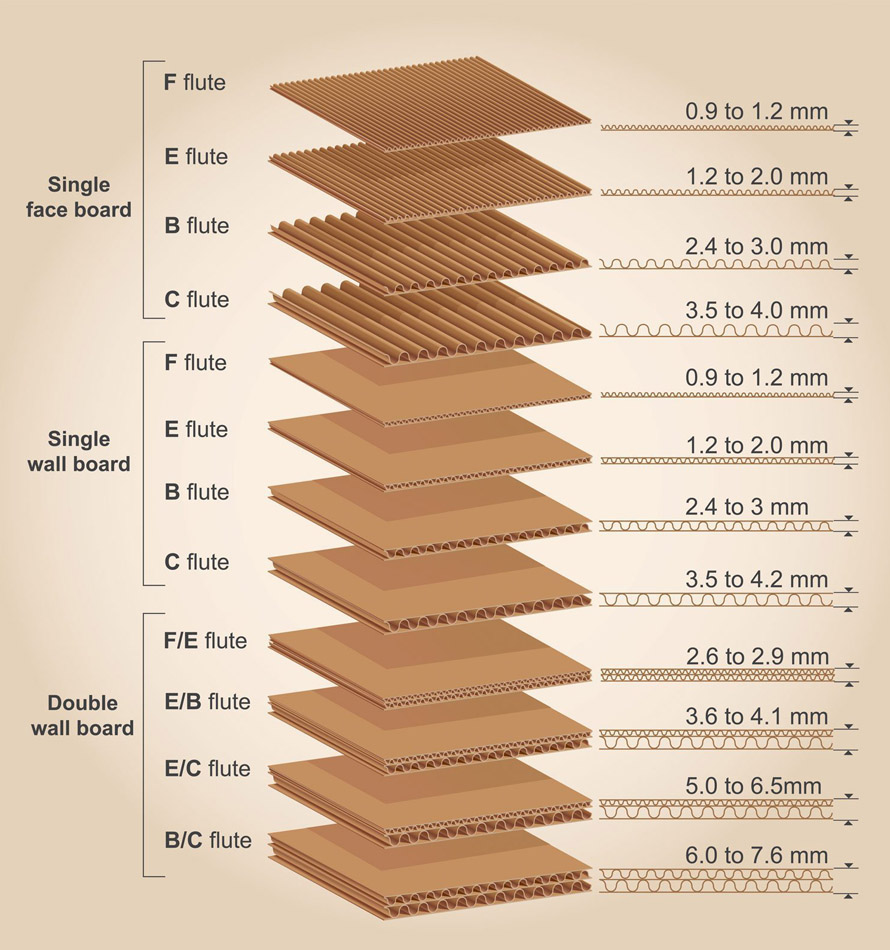

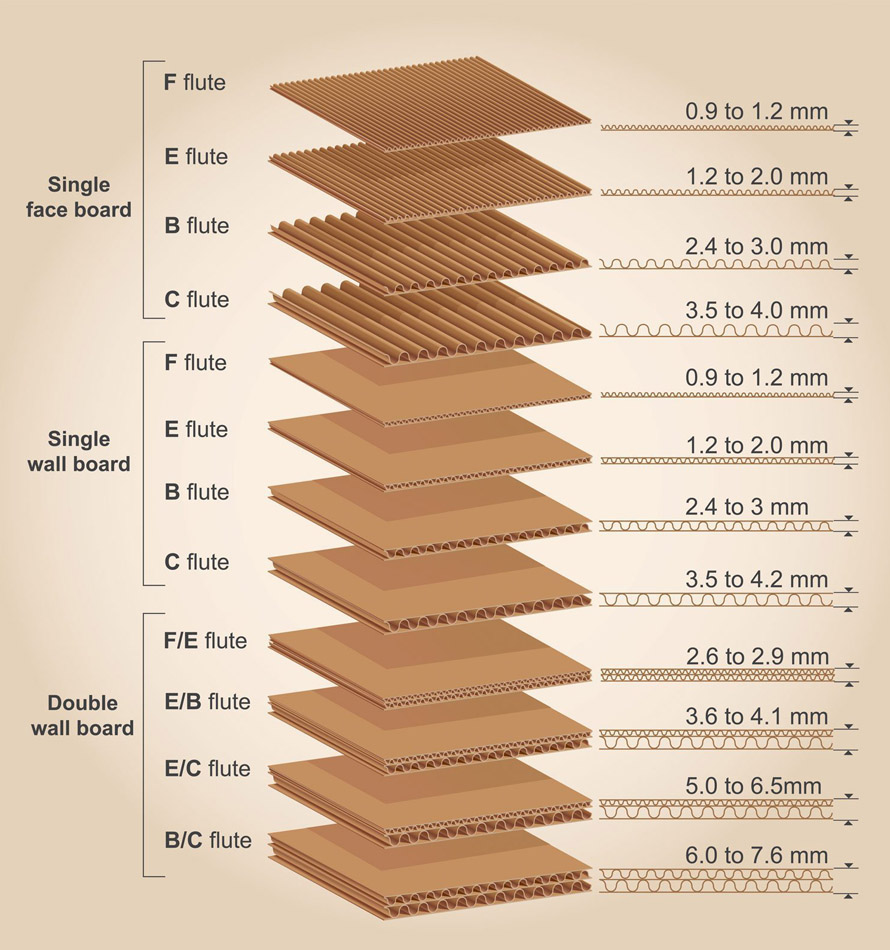

The core sheet wave is divided into: A / B / E / F type, the A type wave is the largest, and the F type is the smallest and the closest.

Features, surface and back colors are both white, but the surface is smooth, and the back is rough. Stiffness of white cardboard is good. Good stiffness, suitable for single-layer carton or paper bags, used to pack items that are not very heavy.

Common weight, 210gsm, 250gsm, 300gsm, 350gsm, and 400gsm

General use, single layer carton, paper card, paper bag, and business cards, etc.

2. Duplex Board or Gray-white board

Features: Surface is white color, but back and paper core color are gray. Normally, surface paper of color corrugated boxes use grayboard. And if there is no requirement for the color of the back paper, it is also a good choice to make a single-layer carton to pack small pieces of lightweight items.

The gray-white board paper used for the surface layer of corrugated board is the carton box surface after the box is made. Therefore, the gray-bottom white board is required to have high strength, folding resistance, tensile resistance, wear resistance, puncture resistance and the like. And a certain water resistance, paper is strong and tough, but also must have good appearance and printability.

Common weight: 250 grams, 300 grams, 350 grams, 400 grams, 450 grams

General use: single-layer carton, corrugated box, paper card, tag, etc.

3. Corrugated sheets

3. Corrugated sheetsCorrugated paper is pressed into a corrugated shape during the production process. After corrugated paperboard is produced, it will provide cardboard elasticity, flat compressive strength, and affect the vertical compressive strength and other properties. Corrugated paper, the paper surface is flat, the thickness should be consistent, there should be no paper defects such as wrinkles, cracks and holes, otherwise the broken ends of the production process will be increased, which will affect the product quality.

Corrugated sheet consists of facial tissue, core paper and inner paper, which add cushion to the packaging and protect the products inside.

Number of layers of sheet: 3 layers of corrugated sheet, 5 layers of corrugated sheet, etc.

The core sheet wave is divided into: A / B / E / F type, the A type wave is the largest, and the F type is the smallest and the closest.

For light packaging, small cartons usually use E-type or F-type corrugated sheet, and large cartons usually use E-type or B-type corrugated sheet;

For heavy packaging, small cartons usually use B-type corrugated sheet, and large cartons usually use 5 layer corrugated sheets such as A+B type, B+B type, B+E type, and E+E type;

For heavy packaging, small cartons usually use B-type corrugated sheet, and large cartons usually use 5 layer corrugated sheets such as A+B type, B+B type, B+E type, and E+E type;

The corrugated inner paper has two kinds of color, yellow and white, what's more, the core paper and the inner paper can also be made to different thicknesses according to requirements.

4. Double Gray Board

4. Double Gray Board

The double-grey board is completely pressed from waste paper pulp and is completely gray.

Double Gray board is an environmentally friendly packaging material. It is not suitable for printing only for the amount of support. Stiffness is much better than corrugated, generally used in inner paper for gift box.

Generally by thickness: 1mm, 1.5mm, 2mm, 2.5mm, 3mm, 3.5mm, etc.

5. Coated Paper

5. Coated Paper

The pigments, adhesives and auxiliary materials are coated and coated on the surface of the paperboard by special equipment. After drying and calendering, a smooth and dense coating is formed on the paper surface to obtain paper with good surface properties and good printing performance. It is called coated paper.

Generally by thickness: 1mm, 1.5mm, 2mm, 2.5mm, 3mm, 3.5mm, etc.

5. Coated Paper

5. Coated Paper The pigments, adhesives and auxiliary materials are coated and coated on the surface of the paperboard by special equipment. After drying and calendering, a smooth and dense coating is formed on the paper surface to obtain paper with good surface properties and good printing performance. It is called coated paper.

There are single copper paper and double copper paper. Single copper paper is smooth on one side, double copper is smooth on both sides, and double copper is the most common.

Features: The color is white, the surface is smooth and shiny, and the double copper is completely the same white on both sides.

Common weight: 80 grams, 105 grams, 128 grams, 157 grams, 200 grams, 250 grams, 300 grams, 350 grams, 400 grams

General use: books, paper bags, advertising paper, business cards, surface paper of box, etc.

6. Kraft paper

Kraft paper is a high-strength wrapping paper made of coniferous sulphate natural color pulp with tough texture, high strength and yellowish brown paper. It can be divided into single-sided light, double-sided light, striped, and non-striped. The quality requirements are slightly different. Kraft paper is divided into U, A and B grades.

Features: there are 2 kinds: yellow or white kraft paper, with thicker fiber, good stiffness, thick paper toughness and not easy to tear

Common weight: 100 grams - 400 grams

7. Specialty Paper

Specialty paper is a paper with a special purpose and a relatively small output. There are many types of special papers, which are collectively referred to as special-purpose papers or art papers. At present, art papers such as embossed paper are collectively referred to as specialty papers, mainly to simplify the noun confusion caused by the variety.

Art paper or special paper is a general calling for embossed paper, aluminum foil paper, perfume paper, pearl paper, sulfuric acid paper, touch paper, etc.

These kinds of papers are various, but basically the above categories, and similar papers have different weight levels.

General use: surface paper of gift box, book cover or inside pages, tags, business cards, etc.

8. Offset Paper

Double gummed paper refers to paper which is coated on both sides of the paper to improve the surface properties of the paper during the papermaking process. The stretchability is small, the absorption of the ink is uniform, the smoothness is good, the texture is tight and opaque, and the water resistance is strong.

Features: white color, surface fiber is thicker than coated paper, no glare, and easy to write

Common weight: 80 grams, 90 grams, 100 grams, 120 grams, 160 grams

General use: notebook, notes, envelopes and other writing prints

9. MDF

Medium Density Fiberboard (MDF) is a kind of density fiberboard. It is made of wood fiber or other vegetable fiber. It is made of fiber, and synthetic resin is applied and pressed under heat and pressure.

According to its density, it can be divided into high density fiberboard, medium density fiberboard and low density fiberboard. The nominal density of the MDF fiberboard ranges from 650Kg/m3 to 800Kg/m3. The medium-density MDF board used in the printing industry is made of wood chips, and it is a kind of wood board. The stiffness is very good, and the big box can be invariant if use this material.

Generally according to thickness: 2mm, 2.5mm, 3mm, 3.5mm, etc.

Common weight: 80 grams, 105 grams, 128 grams, 157 grams, 200 grams, 250 grams, 300 grams, 350 grams, 400 grams

General use: books, paper bags, advertising paper, business cards, surface paper of box, etc.

6. Kraft paper

Kraft paper is a high-strength wrapping paper made of coniferous sulphate natural color pulp with tough texture, high strength and yellowish brown paper. It can be divided into single-sided light, double-sided light, striped, and non-striped. The quality requirements are slightly different. Kraft paper is divided into U, A and B grades.

Features: there are 2 kinds: yellow or white kraft paper, with thicker fiber, good stiffness, thick paper toughness and not easy to tear

Common weight: 100 grams - 400 grams

General use: paper bag, tag

7. Specialty Paper

Specialty paper is a paper with a special purpose and a relatively small output. There are many types of special papers, which are collectively referred to as special-purpose papers or art papers. At present, art papers such as embossed paper are collectively referred to as specialty papers, mainly to simplify the noun confusion caused by the variety.

Art paper or special paper is a general calling for embossed paper, aluminum foil paper, perfume paper, pearl paper, sulfuric acid paper, touch paper, etc.

These kinds of papers are various, but basically the above categories, and similar papers have different weight levels.

General use: surface paper of gift box, book cover or inside pages, tags, business cards, etc.

8. Offset Paper

Double gummed paper refers to paper which is coated on both sides of the paper to improve the surface properties of the paper during the papermaking process. The stretchability is small, the absorption of the ink is uniform, the smoothness is good, the texture is tight and opaque, and the water resistance is strong.

Features: white color, surface fiber is thicker than coated paper, no glare, and easy to write

Common weight: 80 grams, 90 grams, 100 grams, 120 grams, 160 grams

General use: notebook, notes, envelopes and other writing prints

9. MDF

Medium Density Fiberboard (MDF) is a kind of density fiberboard. It is made of wood fiber or other vegetable fiber. It is made of fiber, and synthetic resin is applied and pressed under heat and pressure.

According to its density, it can be divided into high density fiberboard, medium density fiberboard and low density fiberboard. The nominal density of the MDF fiberboard ranges from 650Kg/m3 to 800Kg/m3. The medium-density MDF board used in the printing industry is made of wood chips, and it is a kind of wood board. The stiffness is very good, and the big box can be invariant if use this material.

Generally according to thickness: 2mm, 2.5mm, 3mm, 3.5mm, etc.